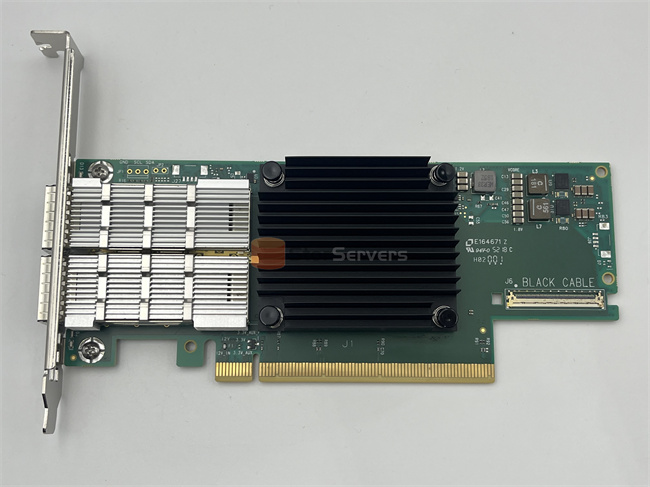

MCX653106A-HDAT Intelligent NIC The Core Engine Driving Next-Generation Data Centers

In the era of artificial intelligence, cloud computing and big data explosion, the traditional network architecture is facing the challenges of bandwidth bottleneck, high latency and wasted CPU resources.The MCX653106A-HDAT intelligent NIC, with its breakthrough performance and intelligent design, has become a strategic solution for enterprises to build high-performance data centers.

1. Redefining the network transmission standard

The MCX653106A-HDAT adopts the industry-leading 200Gb/s transmission rate and supports EDR InfiniBand and 200Gb Ethernet dual-mode protocol. This rate is 5 times higher than that of traditional 40Gb NICs, and it can transfer about 25GB of data (equivalent to 5 4K movies) in 1 second, which is perfectly suited for high throughput scenarios such as AI model training and real-time data analysis, especially for financial high-frequency trading, self-driving decision-making, and other fields with stringent requirements on real-time performance.

2. Unleash the potential of computing resources

Traditional NICs rely on the CPU to process network protocols, resulting in up to 30% of the arithmetic power being occupied.MCX653106A-HDAT achieves improved efficiency through two core technologies:

RoCEv2/RDMA acceleration: Bypassing the operating system kernel, the MCX653106A-HDAT directly exchanges data between memory and GPU/storage, which, combined with GPUDirect technology, improves the training efficiency of AI clusters by more than 40%.

DPU Integration: offloads tasks such as network stack, security encryption, and storage virtualization from CPU to NIC, reducing host power consumption while providing 100Gbps wire-speed encryption capability to safeguard data compliance.

3. Scenario Adaptation

Cloud computing and virtualization: Supporting SR-IOV and VirtIO technologies, a single card can be virtualized to 128 independent network ports, meeting the demand for dense deployment of containers and virtual machines, and increasing resource utilization by 60%.

AI/High Performance Computing: Deep synergy with NVIDIA A100/H100 GPUs accelerates distributed training via SHARP, reducing large-scale model parameter synchronization time by 50%.

Edge and 5G scenarios: Built-in hardware timestamp (PTP) and traffic shaping functions to meet the low-jitter transmission requirements of 5G UPF.

4. Compatible

The MCX653106A-HDAT utilizes a PCIe 4.0 x16 interface and is compatible with mainstream server platforms and supports Linux, Windows, and multiple Hypervisor systems. Its open API allows enterprises to customize network policies, such as dynamic load balancing, QoS priority scheduling, etc., and flexibly adapts to cloud-native environments such as OpenStack and Kubernetes.

5, energy efficiency and cost

Compared to multiple low-rate NIC stacking solutions, the MCX653106A-HDAT can provide 200Gb bandwidth on a single card with a power consumption of only 35W, which, combined with the intelligent thermal design, optimizes the energy efficiency of the data center by 15%. In the long run, its cost can be reduced by 20%-30%, which is especially suitable for ultra-large-scale IDC and hybrid cloud deployment.

The MCX653106A-HDAT is more than just a NIC; it is the core fulcrum of a “data-centric” architecture. With the evolution of DPUs and smart NICs, it is redefining the boundaries of computing, storage and networking. The MCX653106A-HDAT is the key to next-generation infrastructures for organizations seeking zero latency, high security and extreme power efficiency.